- Injection molding excels at repeatability, but only when everything is perfectly tuned.

- High repeatability means saving time, less waste, guaranteed quality, and controlled costs.

- Even minor changes in temperature, pressure, or resin quality can throw consistency off.

- With the right setup, millions of units can be produced with a variation of only ±0.005 inches.

- Output depends on mold quality, precise machines, stable materials, and strict process control.

- For projects that need accuracy, it’s best to work only with expert injection mold specialists.

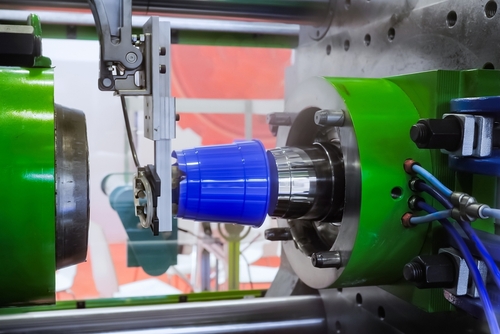

One of the most important benefits of automation is repeatability. However, to achieve that, it’s necessary for the elements involved, including mold, machine, etc. to be in alignment. Even small inconsistencies in temperature, pressure, or mold design can affect the quality of the final product.

That’s why it’s important to choose experienced ceramic and plastic injection mold manufacturers for your project. They will make sure that the mold is engineered to exact specifications, tested for durability, and optimized for consistent production. Keep reading to learn more about repeatability of the injection molding process.

What is the accuracy of injection molding?

Typically, the process can be controlled up to ±0.005 inches, which makes it one of the most reliable methods for part production. This high level of precision reinforces the repeatability of the process across large production runs. Once the mold is properly built, the material is conditioned, and machine settings are optimized, it can produce millions of parts within the mentioned tolerance. Usually, dimensional variation between the first and last part in a large production run is so minimal it’s nearly undetectable to the human eye.

Typically, the process can be controlled up to ±0.005 inches, which makes it one of the most reliable methods for part production. This high level of precision reinforces the repeatability of the process across large production runs. Once the mold is properly built, the material is conditioned, and machine settings are optimized, it can produce millions of parts within the mentioned tolerance. Usually, dimensional variation between the first and last part in a large production run is so minimal it’s nearly undetectable to the human eye.

This level of consistency is achievable because injection molding machines are equipped with advanced controls and automated monitoring systems. These systems allow for precise regulation of variables such as injection pressure, melt temperature, and cooling time. The ability to keep these parameters within strict limits is what makes the process highly repeatable.

Why does repeatability depend on multiple factors?

Repeatability doesn’t rely on the machine alone. It depends on a combination of well-designed factors:

- The mold: A high-quality mold is crucial. It must be engineered to exact tolerances and built with materials that resist wear and thermal distortion.

- The machine: Consistency requires equipment that maintains steady performance throughout the production cycle. High-end machines with closed-loop feedback systems constantly adjust for small deviations, ensuring repeat output.

- The material: Even with the best equipment, results can differ if the resin varies from batch to batch. It’s important to secure reliable suppliers, proper drying, and controlled storage conditions to avoid fluctuations in material properties that could affect repeatability.

- The process: Injection molding is a highly controlled process. Once engineers establish the ideal parameters, they can save and replicate them exactly in future production runs. Any deviation from these parameters, however small, can affect part quality, which is why rigorous process control is crucial.

The benefits of repeatability

Repeatability extends beyond operational efficiency. It plays a critical role in quality assurance, meeting regulatory standards, and maintaining cost control. It helps minimize the need for extensive inspection and reduces material waste from non-conforming products. In industries such as medical devices, automotive systems, and electronics, even minor deviations in part dimensions can compromise safety, functionality, or compliance. That’s why accuracy and repeatability are essential for long-term success.

Looking for trusted ceramic and plastic injection mold manufacturers?

We cater to the needs of both domestic and international clients, so no matter where you’re located, you can rely on us for consistent quality, fast turnaround times, and tailored solutions that align with your specific requirements. Give us a call or get in touch by email at sales@wundermold.com and let us know more about your needs.