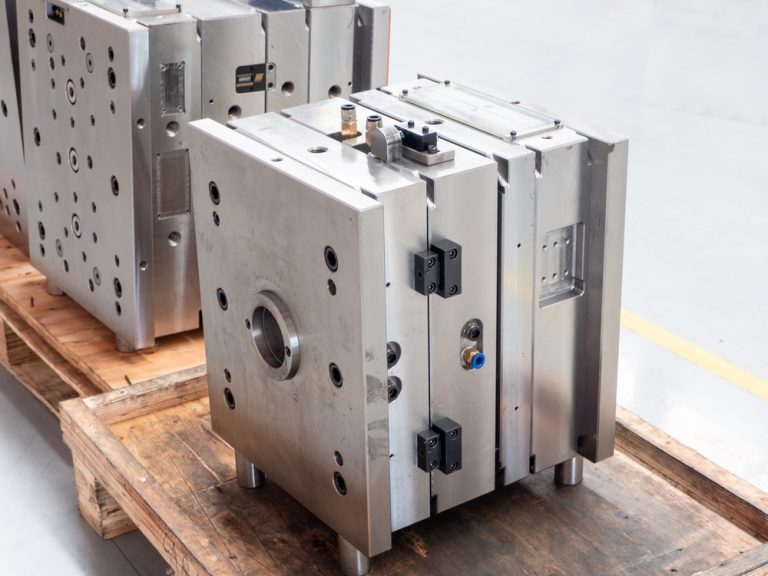

How Injection Molding Supports Complex, Custom Part Designs

Injection molding is one of the most versatile and precise manufacturing methods available today, particularly when it comes to producing parts with intricate designs. Due to the ability to create...