- Design and consultation phase typically takes 1–2 weeks

- Mold fabrication is the longest step, lasting 4–6+ weeks

- Sample molding runs usually take about 1–2 weeks

- Debinding and sintering require an additional 1–2 weeks

- Full process takes 8–12 weeks, depending on part complexity

The process of ceramic injection molding (CIM) involves multiple stages, such as design, tooling, molding, debinding, and sintering, all of which can impact the overall production schedule. In addition, factors like part complexity, material selection, and production volume play a significant role.

Your technical ceramic manufacturer will work closely with you and help you set realistic expectations about lead times. Continue reading to learn more about how long each stage can take and what factors can affect the timeline.

How long does injection molding take?

Understanding the timeline is essential for planning, especially when you’re working with tight development schedules or coordinating with other phases of production. Here’s a breakdown of the typical process:

Initial consultation & design review (1-2 weeks)

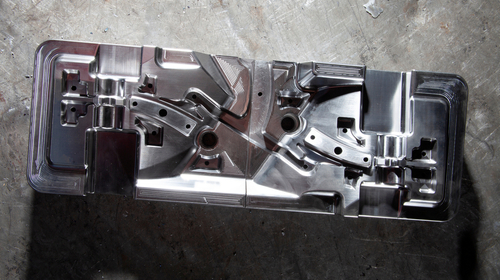

Tooling and mold fabrication (4-6 weeks)

Once the design is finalized, the next step is creating the mold. Tooling is a critical phase and often the longest one in the entire process. It’s essential to create the mold with precision to produce parts that meet tight tolerances. Depending on the complexity of the part and the materials, this step can take anywhere from four to six weeks, or even longer for highly complex designs.

Injection molding (1-2 weeks for sample runs)

With tooling complete, the process of ceramic injection molding can begin. Ceramic feedstock is injected into the mold under controlled conditions to form the green part, which is a component that holds its shape but is still fragile. If you’re starting with a prototype or a small batch, initial sample runs can take about one to two weeks. At this stage, it may still be necessary to make some adjustments to fine-tune the part design or the process before full production begins.

Debinding and sintering (1-2 weeks)

After molding, the green parts undergo debinding, where the binder used in feedstock is removed, typically through solvent, thermal, or catalytic processes. It’s followed by sintering, during which parts are heated at high temperatures to densify and achieve final strength and properties. This stage is time-sensitive and requires precise temperature control to avoid warping or defects. Together, debinding and sintering generally take one to two weeks, depending on part size and material.

Post-processing & quality control (1 week or less)

Depending on your requirements, parts can undergo secondary operations such as polishing. For most standard parts, the final stage takes about a week or less. However, if strict quality inspection processes are in place, this time can be slightly extended to allow for more detailed checks and documentation.

In total, a typical project takes approximately 8 to 12 weeks from start to finish and the best way to stay on track is through clear communication and early planning.

Looking for a reliable technical ceramics manufacturer?

Before embarking on your project, it’s important to find a reputable manufacturer and ask some essential questions to ensure a smooth process. At Wunder Mold, you can rely on our team of experts to provide you with all the necessary information and work closely with you to make sure precise dimensions and all the other requirements are met. Whether you need our services within the U.S. or across the globe, contact us via mail at sales@wundermold.com or by phone, and tell us more about your project.

Before embarking on your project, it’s important to find a reputable manufacturer and ask some essential questions to ensure a smooth process. At Wunder Mold, you can rely on our team of experts to provide you with all the necessary information and work closely with you to make sure precise dimensions and all the other requirements are met. Whether you need our services within the U.S. or across the globe, contact us via mail at sales@wundermold.com or by phone, and tell us more about your project.