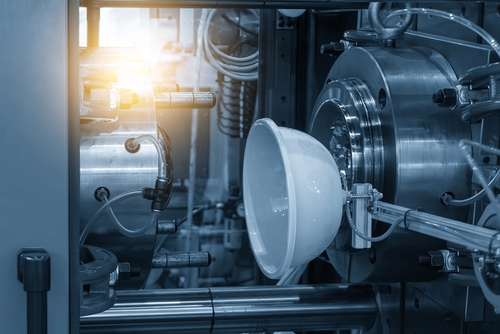

When it comes to staying competitive, efficiency in secondary processes is just as important as production precision and high-quality materials. Trimming, finishing, and inspection often consume a significant amount of time and slow down the entire process, yet they are an essential part of plastic molding manufacturing.

That’s where smart automation comes in. By integrating automated systems in their production line, manufacturers can benefit from increased output and streamlined processes without sacrificing quality. In today’s article, we’ll explore how smart automation complements secondary processes and boosts overall productivity. Let’s dive in!

Which secondary processes benefit most from automation?

When it comes to injection molding, some processes can benefit from automation more than others. These processes typically include:

1. Trimming & deburring

1. Trimming & deburring

When it comes to repetitive and time-consuming tasks, automation delivers the greatest impact. Automated systems can remove excess material or flash from molded components, which would take a human operator a great amount of time and effort. This is especially important in rapid part iteration, where speed and cost-efficiency are the main goals.

2. Multi-part assembly

Many molded components need to be assembled in conjunction with other parts or subcomponents. Automated assembly stations apply vision-guided robotics to move, insert, and attach parts reliably, while reducing the need for human intervention. The result is a consistent repeatability and reduced chance of errors.

3. Quality control

Smart automated systems in inspection can detect imperfections early. From inline vision systems and thermal imaging to laser-based measurements, these methods can measure critical dimensions and find faults that are otherwise difficult or time-consuming to identify.

4. Surface finishing

Processes like sanding, coating, and polishing can be quite labor-intensive. On top of the effort required, these tasks can expose workers to chemicals. With automated surface finishing, manufacturers can protect their employees from harm while simultaneously speeding up the entire process.

How to integrate automated finishing into an injection molding line?

To successfully integrate automation into the process, it’s important to plan and align the automation with the existing workflow carefully. Here’s a step-by-step approach.

1. Map your workflow

Identify repetitive tasks and bottlenecks in the process. Evaluate the ongoing workflow and identify whether trimming, assembly, or inspection is slowing down the production. This can determine which stage of the process could benefit the most from automated systems.

2. Select the right tools

Another critical step is to pick the proper equipment. Utilizing automation should boost the efficiency, whether it’s robotic arms or vision systems for in-line quality control. For the most effective result, it’s important to choose equipment that aligns with your operational demands.

3. Establish layout

Automation systems benefit from thoroughly planned layouts that make the whole process seamless. Modular design allows for operations to expand or scale as the need arises.

4. Implement data-driven monitoring

Automated production lines require strong quality control and monitoring systems to ensure the process stays aligned with quality standards. This includes establishing parameters for monitoring, such as component dimensions, material properties, and surface finish. Additionally, set automation systems to track these parameters continuously during production and log the data for future reference.

5. Support your workforce

Automated systems are becoming a vital part of production. However, human operators are still required to ensure the entire process functions seamlessly, especially when it comes to monitoring, maintenance, and improvements. By continuously training and supporting your employees to work with smart systems, you can ensure that your operations make the most out of automation.

Who specializes in high-quality plastic molding manufacturing?

With industry experience that spans over three decades, Wunder Mold is the go-to choice for reliable injection molding. Our team applies rigorous control checks and ensures each component meets the highest quality standards, while keeping pace with the latest rapid iteration techniques. Whether you’re located close to Peña Adobe Park or anywhere else in the region, reach out today, and let our expertise boost your operations!

1. Trimming & deburring

1. Trimming & deburring