As performance requirements for custom ceramic parts increase, development schedules often tighten at the same time. Design teams are expected to move from concept to production quickly, even when working with advanced oxide materials that require strict process control.

For many manufacturers, the biggest uncertainty isn’t whether a design will work, but how long it will take to deliver consistent, production-ready results. Understanding where time is actually spent makes planning more realistic and helps avoid surprises later. Read on to see how ceramic molding lead times break down and what factors influence them most.

What is the lead time for ceramic injection molding?

Total lead time depends on several interconnected stages rather than a single step. Tool preparation, material conversion, thermal processing, and final finishing all contribute to the schedule. While each project is different, knowing how these stages interact helps teams set expectations and make informed tradeoffs.

Tooling preparation & readiness

The first major contributor to lead time is tool development. This stage includes design review, cavity layout, gating strategy, and fabrication. Geometry complexity, feature density, and tolerance requirements all influence how long this phase takes.

Designs that align well with material flow and shrink behavior tend to move faster, while late changes or unclear specifications often extend timelines. Once complete, the tool establishes the foundation for repeatable ceramic part production, so accuracy at this stage directly affects downstream efficiency.

Material forming & conversion stages

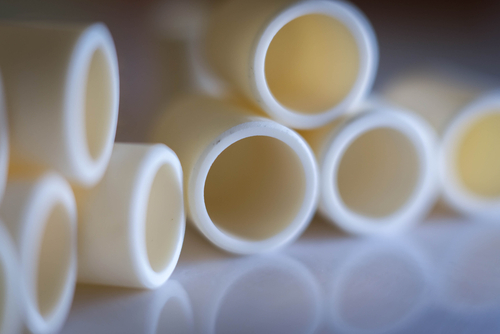

After tooling is ready, production begins with shaping and conversion stages that gradually transform raw feedstock into a dense, functional component. Whether you choose alumina or zirconia for your molded ceramic parts, this phase includes forming, binder removal, and high-temperature firing.

Each step requires controlled conditions and carefully timed cycles. Thicker sections, complex geometries, or mixed wall thicknesses can increase cycle time, while uniform designs tend to move more efficiently through the process. Because these stages rely on thermal stability rather than speed, they often define the minimum achievable timeline.

Thermal processing & shrink control

Firing is not simply a heating step – it’s where final properties and dimensions emerge. Controlled heating and cooling rates reduce internal stress and limit distortion. Shrink behavior must remain predictable for dimensions to land within tolerance. Attempts to accelerate this stage usually introduce risk, so schedules must account for proper dwell times and cooling intervals. This phase rewards patience and precision rather than shortcuts.

Finishing & dimensional refinement

Some designs exit firing very close to final form, while others require additional refinement. Finishing operations may include surface correction, bore adjustment, or interface preparation. The number of features requiring refinement has a direct impact on total lead time. Designs that isolate tight tolerances to a few critical areas typically move faster than those that demand full-surface correction. Planning these requirements early helps prevent unexpected delays.

Inspection & verification steps

Measurement and verification occur throughout production, not only at the end. Early checks confirm dimensional trends, while later inspections validate final specifications. Projects that define inspection criteria clearly tend to move faster because acceptance decisions happen without ambiguity. When requirements change late, additional measurement cycles can add time that was not originally planned.

Factors that shorten or extend schedules

Several variables influence how quickly a project moves from start to finish:

- Geometry complexity and wall thickness variation

- Number of refined features required after firing

- Stability of design revisions during early stages

- Clarity of inspection and acceptance criteria

Projects that address these factors early often experience smoother timelines and fewer delays.

Planning lead time realistically

No two projects follow the same schedule, and many require performance tests for ceramic parts before scaling into full production, which impacts the total timeline. However, most delays trace back to uncertainty rather than process limitations. When teams understand how tooling, conversion, and finishing contribute to overall duration, they can plan development milestones more accurately.

Who delivers custom ceramic parts with predictable lead times?

At Wunder-Mold, we help manufacturers plan realistically and move efficiently from early design to full production. With decades of experience working with advanced oxide materials, our team understands how tooling preparation, thermal processing, and finishing steps shape overall project timelines. We work closely with you to identify potential schedule drivers early, reduce uncertainty, and ensure every stage supports consistent, production-ready results. If you’re looking to align performance requirements with achievable lead times, contact us today to discuss your project and get clarity from the start.