Design teams working in high-temperature, high-wear, or electrically demanding environments often reach a point where material choice becomes critical. Selecting the wrong option can lead to premature failure, dimensional drift, or performance limits that no amount of design optimization can fix.

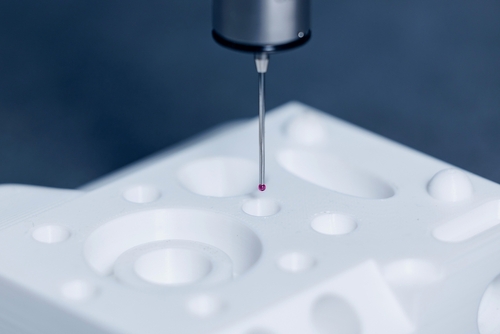

For ceramic parts manufacturers evaluating advanced oxide solutions, the choice usually quickly narrows to two proven candidates: alumina and zirconia. Each offers distinct strengths, but they solve different problems. Read on to understand how to decide whether alumina or zirconia injection molding fits your application best.

What is the difference between zirconia and alumina?

Although both materials belong to the same family of advanced oxides, their behavior under load, heat, and stress varies in important ways. Understanding those differences helps engineers make informed decisions when choosing between alumina and zirconia for their parts, based on real operating conditions rather than assumptions.

Mechanical strength and toughness

Alumina is known for its hardness and compressive strength. It performs exceptionally well in applications where surfaces experience abrasion, sliding contact, or repeated wear. However, it is relatively brittle, meaning it does not tolerate sudden impact or tensile stress as well as some alternatives.

Zirconia behaves differently. Its internal crystal structure allows it to absorb stress more effectively, giving it higher fracture toughness. This makes it better suited for designs where impact resistance or resistance to crack propagation matters. When a component must withstand mechanical shock or cyclic stress, zirconia often provides a wider safety margin.

Thermal behavior and stability

Alumina maintains structural integrity at very high temperatures and remains stable across wide thermal ranges. It is commonly used where heat exposure is continuous and predictable, such as furnace fixtures or electrical insulation near hot zones. Its thermal expansion remains low and consistent, which helps preserve dimensional accuracy.

Zirconia can also tolerate heat but expands more than alumina as temperature rises. This characteristic does not make it unsuitable for thermal environments, but it does require careful consideration when tight tolerances or mating interfaces are involved. In designs where thermal cycling is aggressive, expansion behavior becomes a deciding factor.

Wear resistance and surface durability

For applications involving friction, particulate exposure, or sliding contact, alumina’s hardness provides excellent resistance to surface degradation. Components retain shape and finish over long service periods, reducing the need for frequent replacement.

Zirconia offers good wear resistance as well, though its advantage lies more in toughness than pure hardness. In situations where surface durability must coexist with impact resistance, zirconia can outperform alumina by avoiding surface chipping or microcracking under load.

Electrical and insulating performance

Alumina excels in electrical insulation. Its dielectric properties remain stable even at elevated temperatures, making it ideal for housings, substrates, and isolation features in electronics and power systems. It reliably separates conductive elements without distortion or degradation.

Zirconia also provides insulating behavior, but it is typically selected for mechanical performance rather than electrical isolation. When insulation is the primary requirement, alumina is often the preferred option.

Density and weight considerations

Zirconia is denser than alumina. That added mass can be beneficial in applications requiring inertia or vibration damping, but it may be undesirable where weight reduction is a priority. Alumina offers a lighter alternative while still delivering strong mechanical and thermal performance.

Cost and production efficiency

From a production standpoint, alumina generally offers broader availability and lower material cost. It also processes efficiently for many geometries, which can help control budgets and simplify planning around lead times in ceramic manufacturing.

Zirconia tends to carry higher raw material and processing costs. However, that investment is often justified when its toughness improves long-term reliability and helps maintain consistent results across repeated ceramic part production runs, especially in demanding applications.

Matching material to application needs

Neither option is universally better. Alumina suits applications that prioritize hardness, insulation, thermal stability, and cost efficiency. Zirconia fits designs that demand toughness, impact resistance, or resistance to crack growth. The right choice depends on how the component will be loaded, heated, and handled throughout its life cycle. Teams often validate this choice through early trials, using pilot builds to test ceramic parts before moving into full-scale production.

Who are experienced ceramic parts manufacturers for high-performance applications?

At Wunder-Mold, we help manufacturers select the right material from the start, so performance expectations align with real operating conditions. With decades of experience producing advanced oxide components, our team understands how material behavior affects durability, tolerances, and long-term reliability.

We work closely with you to evaluate design requirements, service environments, and production goals before recommending the best solution. If you’re deciding between alumina and zirconia and want confidence in your choice, reach out to us today and let’s discuss your application.