Reliable custom plastic injection molding companies in the USA produce complex and precise plastic components with exceptional dimensional accuracy and surface finish. By utilizing computer-controlled systems and advanced molds, this process offers remarkable advantages, including rapid production cycles, reduced material waste, and cost-effectiveness.

Additionally, it grants the flexibility to create intricate designs and incorporate various additives, such as colorants and reinforcements, enhancing the functionality and aesthetics of the final product. Keep reading to learn more about the advantages of this process.

What are the advantages of plastic injection molding?

The scientific application of this process paves the way for innovative solutions, revolutionizing manufacturing practices across diverse sectors. Here are some essential advantages it brings:

Precision and complexity

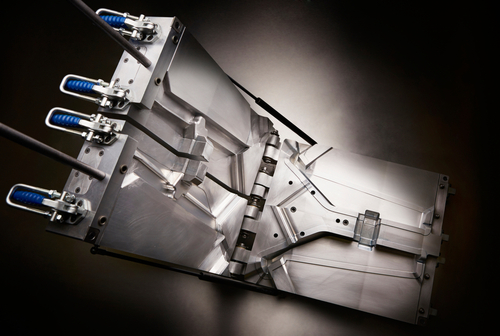

This precision is achieved through advanced mold design and the use of computer-controlled systems, which regulate temperature, pressure, and injection speed. As a result, manufacturers can achieve superior dimensional accuracy, minimizing the need for additional finishing operations and optimizing overall production efficiency.

Efficient production cycles

Remarkably fast production cycles making this process an ideal choice for large-scale manufacturing. It allows for high-speed production, enabling the rapid creation of identical components.

Furthermore, the utilization of multi-cavity molds allows for the simultaneous production of multiple parts in a single cycle, significantly increasing productivity. This efficiency is particularly advantageous in industries with high-volume production requirements, as it helps meet tight deadlines and satisfy market demands promptly.

Material versatility

Thermoplastics, such as polyethylene, polypropylene, and polycarbonate, are commonly used materials due to their excellent properties, including durability, chemical resistance, and flexibility.

Additionally, specialized materials like biodegradable polymers and high-performance plastics can be utilized to meet specific application requirements. Moreover, this process allows for the incorporation of additives, such as colorants, UV stabilizers, and flame retardants, enhancing the functionality and aesthetics of the final product.

Cost-effectiveness

Custom plastic injection molding offers significant cost advantages over alternative manufacturing methods, particularly for large production runs. The initial tooling costs can be relatively high, as molds need to be designed and manufactured. However, once the molds are created, the per-unit cost decreases significantly due to the high efficiency of the process, minimizing material waste and labor costs.

Additionally, the ability to produce complex parts with a single operation eliminates the need for multiple manufacturing steps, further reducing production costs and increasing overall profitability.

Design flexibility

The process allows for the creation of intricate and detailed designs, enabling the production of components with complex features, such as thin walls, undercuts, and internal threads. Design modifications can be easily implemented by modifying the mold, facilitating product evolution and customization.

This adaptability allows manufacturers to quickly respond to market demands, stay ahead of competitors, and continuously improve product performance.

Superior surface finish

The molds used in this process are typically made of high-quality steel, resulting in smooth and polished surfaces on the molded parts. This eliminates the need for additional surface finishing operations, saving time and cost. The high level of surface finish makes it suitable for applications where appearance and texture are critical, such as consumer electronics, automotive interiors, and medical devices.

What are the best custom injection molding companies in the USA & globally?

When you need premium-quality plastic molded parts or you’d like to know more about the environmental sustainability of the process, Wunder Mold is the team you can rely on. With lengthy experience and comprehensive knowledge, we deliver high-precision components for applications across different industries. You can give us a call or reach out to us by email at sales@wundermold.com and tell us in detail about the parts you need.