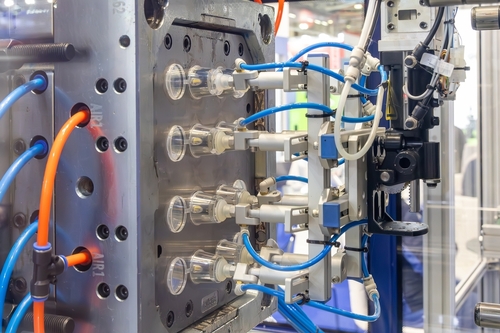

The process of injection molding has been acknowledged as both efficient and versatile among other processes of industrial manufacturing. This technology allows for precise and intricate designs and yields sturdy and highly uniform products for various industries, such as consumer electronics, medicine, automotive, aviation, and more.

With experienced and reliable providers of ceramic and plastic injection mold services, you can create complicated parts of high quality, no matter the volume. Read on to learn more about the numerous benefits of injection molding.

What are the benefits of injection molding?

What are the benefits of injection molding?

By combining precision, efficiency, and cost-effectiveness, the process is ideal for production needs of the modern age. Here are the top benefits it brings:

High precision and repeatability

Injection molding can produce parts with tight tolerances and high accuracy. Once the mold is designed and tested, each part produced is identical to the last. This repeatability is essential in industries where consistency is of high importance, such as medical devices or automotive components.

Fast production cycles

Speed is another major advantage. Depending on the complexity and size of the part, cycle times can be as short as a few seconds. This allows manufacturers to meet tight deadlines and quickly scale up production in case of increased demand.

Wide range of material options

The process supports a broad selection of materials, most commonly thermoplastics like ABS, polycarbonate, nylon, and polyethylene. They offer different properties in terms of strength, flexibility, chemical resistance, and temperature tolerance, allowing engineers to meet specific performance requirements.

Beyond plastics, the process can also use ceramic powders combined with a binder material to form complex, high-precision parts that are later sintered at high temperatures. It’s ideal for applications that require extreme hardness, wear resistance, and high-temperature performance, such as aerospace components, medical implants, and electronics.

This versatility allows designers to choose the right solution for everything from durable consumer goods to advanced technical applications.

Design flexibility and complexity

Experts can produce complex shapes, fine details, and multi-functional parts with relative ease. Features like undercuts, threads, and logos can be incorporated directly into the mold design and reduce or eliminate the need for secondary operations.

Low waste

Unlike traditional machining or fabrication, injection molding produces very little waste. Excess material can often be recycled and reused, which makes the process more sustainable. In addition, innovations in biodegradable and recycled resins are opening new opportunities for sustainable production.

Reduced assembly time

By integrating multiple features into a single molded part, the process can help reduce the number of components needed and streamline the process of assembly. Insert molding and overmolding also allow different materials or components to be combined in one step.

Cost-effectiveness for high volumes

Once designers create the initial mold, the cost per part becomes very low. This makes it especially favorable for high-volume production. Whether you’re manufacturing thousands or millions of parts, the process remains consistent and efficient, which makes large-scale production more cost-efficient.

Who offers quality ceramic & plastic injection molding services?

With nearly three decades of experience in the industry, Wunder Mold is the company you can rely on to provide you with premium-quality custom molded ceramic or plastic parts that meet the exact requirements of your application. We’ll work closely with you to understand your needs and provide you with the best solution. We work with both domestic and international partners, so feel free to reach out to us wherever your business is located. You can contact us by phone or email at sales@wundermold.com and let us know what we can do for you.