Advanced ceramic materials offer exceptional mechanical, thermal, and electrical properties which make them ideal for use in a wide range of high-temperature applications, including aerospace, automotive, chemical processing, and power generation. They exhibit excellent resistance to heat, wear, corrosion, and thermal shock, making them ideal for use in harsh operating conditions. Their high strength, hardness, and toughness allow them to withstand extreme loads and pressures. Reliable technical ceramic manufacturers use them in various applications. Keep reading to learn more about their benefits in high-temperature applications.

What are the advantages of using ceramics at high temperatures?

Exceptional properties of advanced ceramics make them highly suitable for high-temperature applications. Here are some of the important benefits:

Thermal stability

They have a very high melting point, typically in excess of 1000°C. They can operate at much higher temperatures than most other materials. This makes them ideal for use in applications where heat resistance is critical, such as furnaces, kilns, and gas turbines. They can also withstand rapid temperature changes without cracking or breaking, making them resistant to thermal shock.

Mechanical strength and hardness

Ceramics boast high compressive strength and they can withstand heavy loads without deforming or breaking. They are also much harder than metals, which makes them highly resistant to wear and abrasion. This is why they’re an excellent option for applications that require high wear resistance, such as bearings, valves, and cutting tools.

Chemical resistance

Excellent chemical resistance makes these materials ideal for use in harsh chemical environments. Unlike many metals, they are not susceptible to corrosion or oxidation, even at high temperatures. They are also highly resistant to chemical attack, making them suitable for use in applications where exposure to acids, bases, and other corrosive substances is likely.

Electrical resistance

Advanced ceramics have exceptional electrical properties. They are highly insulating and can withstand high voltages without conducting electricity. They are an excellent material choice for electrical insulators and components that require high electrical resistance, such as electronic substrates and capacitors.

Design flexibility

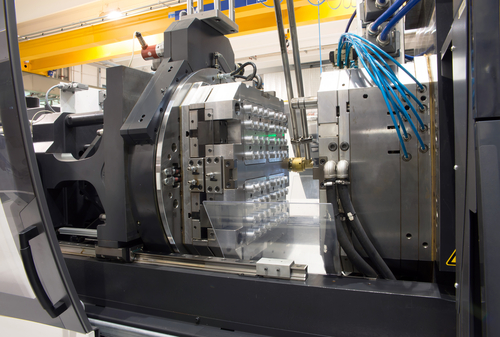

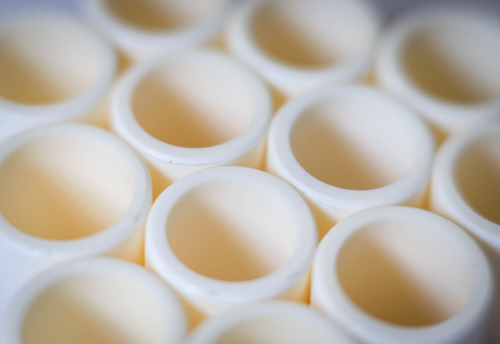

These materials can be formed into a variety of complex shapes and sizes using a range of manufacturing techniques, including casting, extrusion, machining, and injection molding. This makes them suitable for use in a wide range of applications, from small electronic components to large industrial machinery.

Biocompatibility

Some ceramic materials, such as alumina and zirconia, are biocompatible and can be used in medical implants and devices without causing adverse reactions. This makes them a perfect solution for medical applications, where biocompatibility is essential.

Environmentally friendly

Unlike many other materials, ceramics are not derived from non-renewable resources, such as petroleum. They are also highly durable and can withstand many years of use without degrading or breaking down. This makes them an excellent alternative to other materials that have a higher environmental impact.

Who is the best technical ceramics manufacturer?

We boast over 29 years of experience and take pride in our unwavering commitment to high quality and excellent customer service. We work with clients across different industries and parts of the world to deliver high-precision parts by utilizing state-of-the-art technology and adhering to the highest industry standards. Email us at sales@wundermold.com or reach out to us by phone.