High-performance ceramics are redefining what’s possible in extreme environments, whether it’s intense mechanical stress or scorching hot heat. These advanced materials excel where traditional metals and polymers often fall short. They offer excellent durability, thermal stability, and resistance to wear. Ceramic materials companies can create precision-engineered parts for various industries, including energy, automotive, and aerospace. Keep reading to learn more about why high-performance ceramics perform exceptionally well in extreme environments.

What is high performance ceramics?

Whether it’s a chemical processing tool or a rocket engine part, these ceramics are the perfect choice for demanding applications because of their favorable properties:

Exceptional thermal stability

One of the primary characteristics of technical ceramics is their ability to withstand extreme temperatures without compromising performance. Materials like silicon carbide, alumina, and zirconia maintain their structural integrity at temperatures that far exceed those that are tolerable for metals or polymers.

For example, in aerospace, ceramic parts are used in turbine engines and heat shields, where they endure extreme temperatures while maintaining their strength and shape.

Superior wear and corrosion resistance

When operating in harsh environments, conventional materials can rapidly degrade. However, technical ceramics exhibit resistance to both. Alumina and silicon carbide are widely used in applications that require extreme hardness and abrasion resistance such as cutting tools, bearings, and pump seals. In chemical processing, ceramic parts such as valves and pipes are preferred for their ability to resist corrosion from acids, alkalis, and other aggressive chemicals.

Excellent mechanical strength

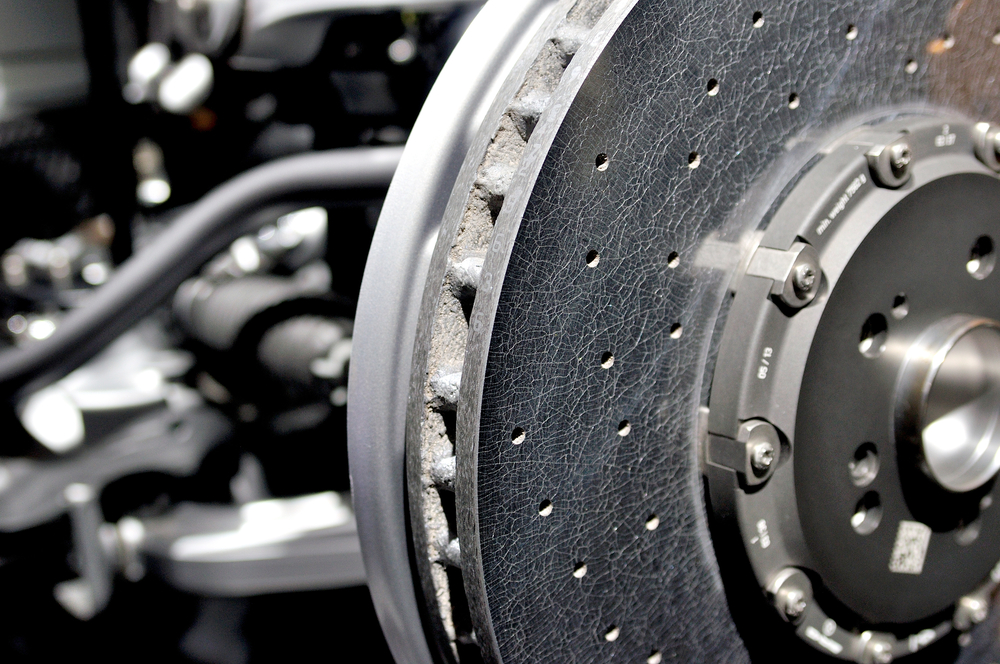

Despite their lightweight nature, these ceramics feature high mechanical strength and excellent resistance to crack propagation, even under heavy loads or impact. This makes them suitable for components like automotive brake pads, engine parts, and structural elements in industrial machinery.

Electrical and thermal insulation

High-performance ceramics also excel as electrical insulators, which makes them ideal for high-voltage and high-frequency applications. Those like alumina and zirconia are commonly used in electronic divides, semiconductor manufacturing, and power systems.

In addition to electrical insulation, they also provide excellent thermal insulation, which helps to manage heat transfer in applications like heat exchangers and thermal barriers.

Key applications across industries

Because of their versatility, technical ceramics are used across a wide range of industries, including:

- Aerospace: Components like turbine blades, nose cones, and thermal protection systems benefit from ceramics’ heat resistance and lightweight properties.

- Automotive: From catalytic converter substrates to brake discs, these materials enhance both durability and fuel efficiency.

- Energy: Ceramics are essential in fuel cells, nuclear reactors, and solar panels, where they improve performance and longevity.

- Medical: In the medical field, they’re used for implants, dental restorations, and surgical tools due to their strength and biocompatibility.

- Chemical processing: They provide corrosion-resistant solutions for reactors, mixers, and other critical equipment.

Advancing science

Recent advancements in material science and manufacturing techniques are further expanding the capabilities of technical ceramics. For example, innovations in nanotechnology and composite ceramics are enhancing material properties such as toughness and thermal conductivity, which opens new doors for applications in extreme environments.

Who are the leading ceramic materials companies?

If you’re interested in learning more about how to improve thermal shock resistance in technical ceramics, or want to explore ceramic sintering in detail, reach out to Wunder Mold. With years of experience in the industry and a crew of diligent experts, we can provide you with high-quality parts that meet your exact requirements. We work with both domestic and international clients, so feel free to contact us and let us know more about the specificities of your project. Reach out to us by phone or send us an email at sales@wundermold.com.