Injection molding is an important industry manufacturing process of high versatility and efficiency. It involves the injection of molten material into a pre-designed mold to cool and solidify. The process has a wide application across industries, from automotive and aerospace components to household items.

In the modern age, you can reach out to a reliable ceramics or plastic injection molding company for parts of any complexity and design and expect a high-quality product. In today’s article, we give you a short overview of the history and development of the injection molding process.

What is the history of injection molding?

The process has been present for over 150 years, with the earliest origins traced back to the mid-19th century. Let’s dive deeper into the history and explore the evolution of injection molding:

Invention

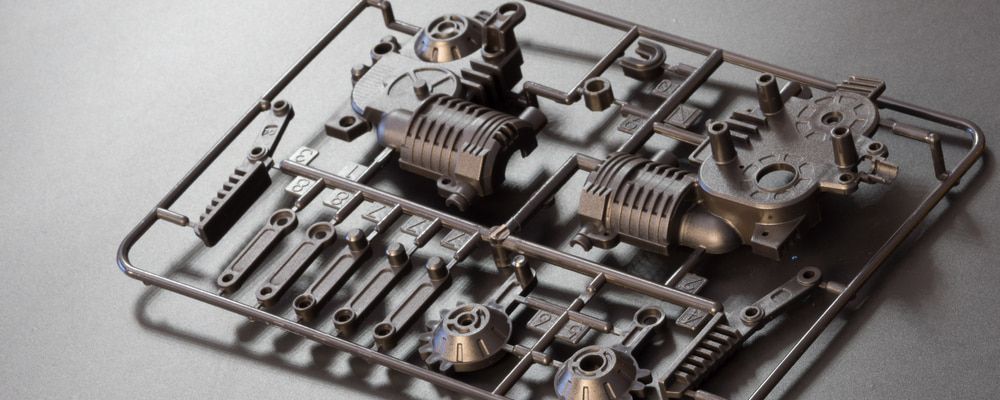

The industry of the 19th century was marked by a growing demand for efficient production of plastic materials as well as the experimenting of different inventors with heated materials to create molded products. As a result, the process of rubber injection molding was developed in 1872. It was used to produce small parts for different applications, including household goods and toys.

The first injection molding machines were simple and consisted of a plunger mechanism that was used to inject molten plastic into the mold.

Evolution

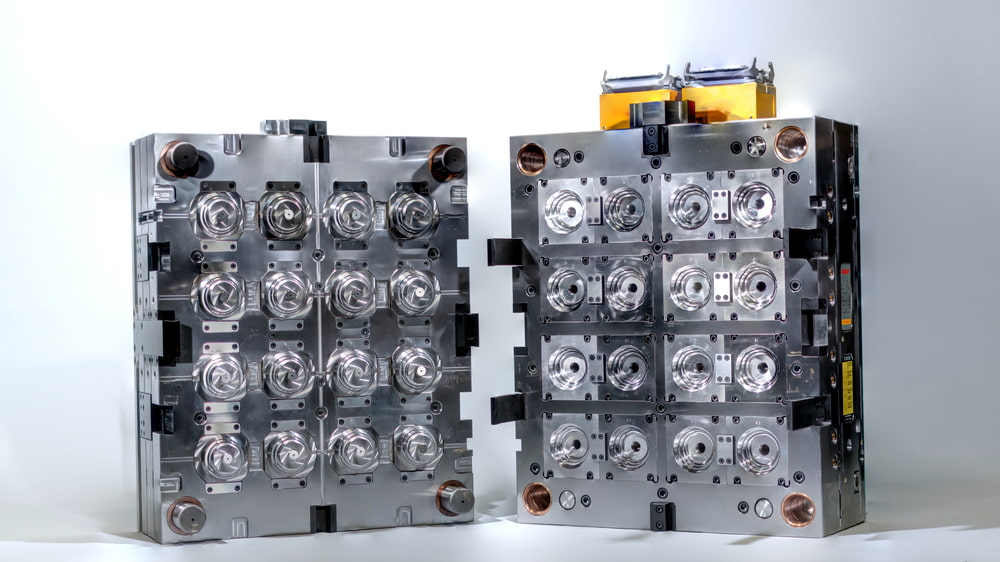

In the late 19th and early 20th centuries, the field of thermoplastics witnessed significant advancements that led to the development of more complex machines, designed to operate at higher temperatures and pressures, allowing for the production of more complex and larger parts.

Over the following decades, the process expanded rapidly. Advances in the design of machines and materials during the 1930s and 1940s resulted in the production of parts with more intricate details and shapes.

Significant milestones in the evolution of this process include:

- Screw injection machine development offered enhanced control over the consistency and speed of molten material.

- Computer-assisted manufacturing allowed for precise control over the process, improving the quality of finished products.

- Material advancements helped expand the application of the process.

- Development of micro molding allowed for the production of extremely precise and small parts.

Modern age

Today, injection molding stands as one of the most widely applied manufacturing methods worldwide. It has been improved and refined to become more efficient, more precise, and faster than it has ever been. Moreover, with continual improvements and the development of new technologies and ceramic and plastic materials, it continues to drive innovation in the manufacturing industry, with a growing focus on sustainability.

Looking for a trusted ceramic & plastic injection molding company?

Whether you live in the United States or across the globe, feel free to send us an email at sales@wundermold.com or dial our number and tell us all about the parts you need. Get in touch with us today!