- CIM blends ceramic strength with injection molding precision

- Feedstock mixes fine ceramic powders with binders for molding

- Debinding removes binders, leaving fragile but accurate parts

- Sintering fuses particles, giving strength and durability

- CIM enables complex, repeatable, high-performance parts

Ceramic injection molding (CIM) may sound like something straight out of a science fiction novel, but it’s one of those behind-the-scenes technologies shaping a wide variety of modern industries, from electronics to aerospace. If you’ve wondered how complex, high-performance ceramic components are made in bulk without breaking the bank, this is it. CIM combines the versatility of plastic injection molding with the durability and robust performance of advanced ceramics.

What is the process of injection molding ceramics?

At its core, CIM follows a similar blueprint to plastic injection molding, but with a few crucial extra steps due to the unique nature of ceramics. Here’s the breakdown of the process:

Feedstock preparation

It all starts with creating a feedstock, which is a blend of fine ceramic powders and a carefully selected binder system. The binder then acts as a temporary glue that gives the ceramic powder its plastic-like flow property so it can be injected into the mold.

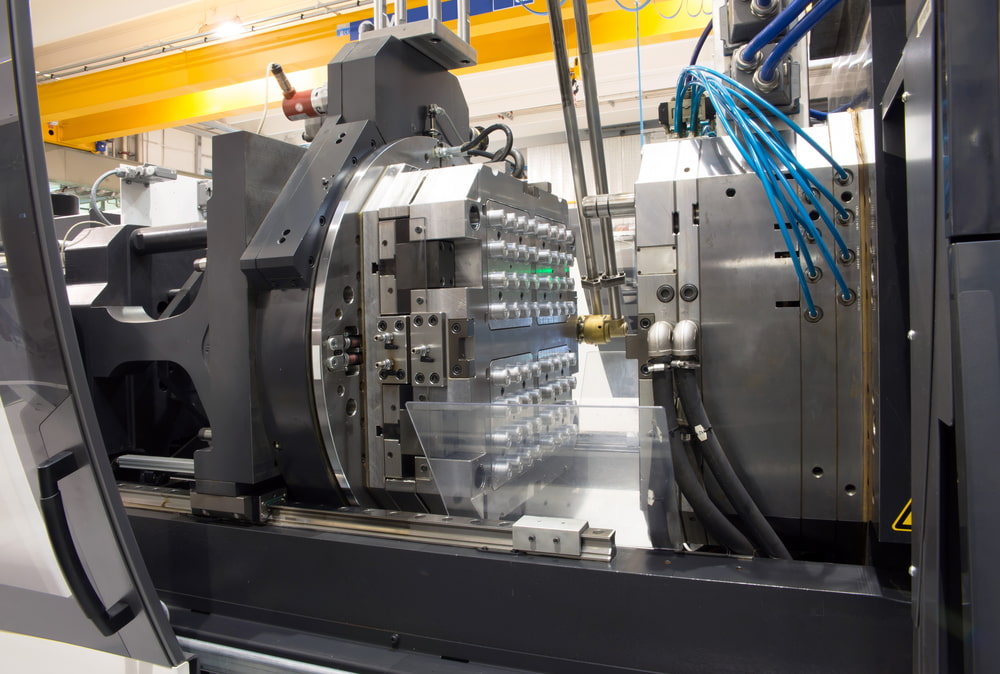

Injection molding

The feedstock is heated and injected into the precision molds under high pressure. At this stage, the ceramic-binder mix behaves like molten plastic and fills every feature of the cavity. This allows manufacturers to create intricate shapes with tight tolerances.

Debinding

The binder is removed when the part known as the ‘green body’ is ejected. This step is called debinding. Depending on the material system, it may involve solvent extraction, thermal treatment, or a combination of the two. Removing the binder leaves a fragile but accurately shaped ceramic form.

Sintering

Finally, the debound part is sintered at high temperatures. During this process, ceramic particles fuse to eliminate porosity and achieve full density. This step gives components their final strength, hardness, and advanced thermal properties.

At the end of the process, you get a fully dense ceramic part that maintains the exact geometry of the molded shape but with advanced performance characteristics that only ceramics can offer.

Why manufacturers choose ceramic injection molding?

Cim solves a very specific problem: how to produce high-performance ceramic components in high volumes while keeping costs within reasonable limits. With traditional shaping methods like pressing and machining limited in geometry and high costs for complex parts, ceramic injection molding enables near-net-shape production, minimizing the need for costly finishing. Here are the biggest advantages of CIM:

- Complex geometry: Undercuts, fine details, and thin walls are all an option.

- High repeatability: Perfect for scaling production without sacrificing quality.

- Material versatility: Alumina, zirconia, and silicon nitride are just some of the high-quality ceramics used in CIM, each with its own unique properties.

- Performance boost: Manufactured parts can resist extreme wear, corrosion, and heat, making them indispensable in high-end modern-day applications.

Which company specializes in manufacturing high-end custom ceramic parts?

Whether you’re looking for answers before embarking on injection molding, need some clarification on projected timeframes, or want to learn more about dimensional accuracy, don’t hesitate to write us at sales@wundermold.com or call us directly over the phone, and we’ll guide you through all the intricacies of the process. Get in touch with us today!