Aluminum oxide is recognized for its exceptional dielectric properties and thermal conductivity, which makes it paramount within the electronics industry. Its electrical insulating characteristics make it an ideal choice for the production of high-performance insulators, circuit substrates, capacitor components, and other alumina ceramic parts. Moreover, its thermal conductivity facilitates efficient heat dissipation, critical for the reliable operation of electronic devices. In this article, we’ll take a close look at its indispensable use in the electronics sector.

Aluminum oxide is recognized for its exceptional dielectric properties and thermal conductivity, which makes it paramount within the electronics industry. Its electrical insulating characteristics make it an ideal choice for the production of high-performance insulators, circuit substrates, capacitor components, and other alumina ceramic parts. Moreover, its thermal conductivity facilitates efficient heat dissipation, critical for the reliable operation of electronic devices. In this article, we’ll take a close look at its indispensable use in the electronics sector.

What are the uses of aluminum oxide in the electronics industry?

This compound finds widespread use in various electronic components and systems, contributing to their performance, reliability, and longevity:

Insulating substrates

Al2O3 is frequently employed as a substrate material for integrated circuit (IC) packaging and power electronic modules. Its high dielectric strength and electrical insulating properties make it an excellent choice to provide electrical isolation and support for electronic components, preventing short circuits and ensuring signal integrity.

Thermal management

In electronic devices, efficient heat dissipation is paramount to prevent overheating and ensure optimal performance. Aluminum oxide’s high thermal conductivity enables it to serve as a thermally conductive substrate for power electronics, helping to dissipate heat generated by components such as transistors and diodes. This property is particularly vital in devices like LED packages and high-power amplifiers.

Ceramic capacitors

The compound is common in the production of ceramic capacitors, thanks to its high dielectric constant and stability over a wide range of temperatures. They are widely employed in electronic circuits for coupling, decoupling, filtering, and timing applications.

High-frequency components

In microwave and radio-frequency applications, Al2O3 is used as a substrate material for various components, including antennas, resonators, and filters. Its dielectric properties allow for the precise control of signal propagation and filtering in high-frequency circuits.

Thick film technology

Aluminum oxide-based thick-film pastes are utilized for the deposition of resistors, conductors, and dielectric layers on ceramic substrates. These pastes are integral to the fabrication of hybrid integrated circuits, sensor devices, and multilayer ceramic capacitors.

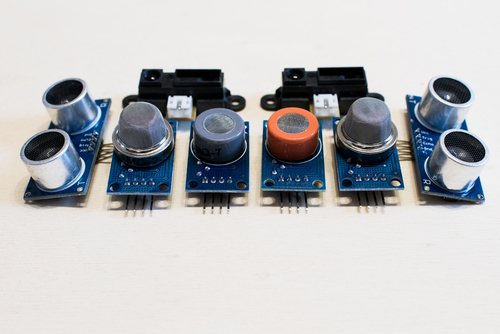

Sensor technologies

The compound’s chemical stability, electrical insulation, and thermal conductivity make it an excellent choice for sensor applications. It’s often used as a substrate for gas sensors, temperature sensors, and pressure sensors, facilitating accurate and reliable measurements.

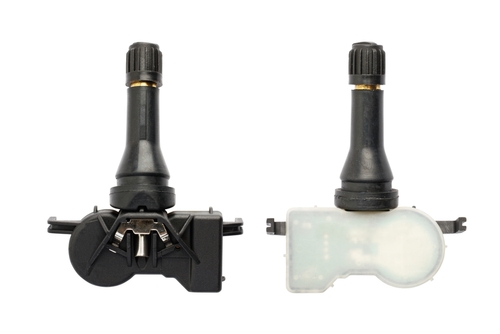

Electronic packaging

Al2O3 is employed in electronic packaging as a hermetic and insulating material. It helps seal electronic components and modules to protect them from environmental factors such as moisture, dust, and chemicals. This is particularly important in aerospace, automotive, and military electronics.

Alumina ceramics for RF applications

Alumina is widely used in the fabrication of substrates and packages for radio-frequency (RF) and microwave circuits. It provides excellent electrical properties, mechanical strength, and thermal performance for RF applications.

Piezoelectric ceramics

The compound, often doped with various additives, is utilized in the production of piezoelectric ceramics which are crucial for the generation and detection of acoustic waves and vibrations in electronic devices such as ultrasonic sensors, piezoelectric transducers, and inkjet printers.

Who can produce high-precision alumina ceramic parts?

We leverage years of experience and state-of-the-art technology and equipment to provide you with products that feature the exact required properties. Our services are available countrywide as well as worldwide, so feel free to reach us by email at sales@wundermold.com or give us a call.