Metal part production allows for tight tolerances and offers favorable properties such as excellent stiffness and strength. However, advancements in plastic injection mold manufacturing and new materials that offer characteristics comparable to metals has caused industries to replace their metal parts with plastic. Understanding the benefits of plastic over metal can help you opt for the right materials for your project and achieve the necessary end-product properties.

Why should I use plastic injection molded parts?

Selection of appropriate materials, use of innovative molding principles, and careful planning and design affect tolerances, precision, and accuracy of plastic parts. These elements include sophisticated sensor technology that tracks parameters inside the mold in real time, machine processing parameters, melt flow index, and material preparation.

Selection of appropriate materials, use of innovative molding principles, and careful planning and design affect tolerances, precision, and accuracy of plastic parts. These elements include sophisticated sensor technology that tracks parameters inside the mold in real time, machine processing parameters, melt flow index, and material preparation.

A rigorous quality system monitors every step of the process for plastic injection molding, ensuring high-performance plastic products and parts that have numerous benefits over metal parts:

Lower cost

Several factors within the process of plastic part manufacturing result in lower production costs:

- There’s no need for the secondary process that prevents oxidation

- It’s possible to eliminate some assembly steps

- Plastic materials cost less than metal

- It’s possible to eliminate some machining operations

- Plastic is lighter than metal, resulting in lower shipping costs

- Plastic can be molded in graphics and color, so there’s no need for painting

Lighter weight

Plastic materials are lighter than metal, which facilitates many underlying processes:

- A product can move faster

- It’s less burdensome if a person carries it

- It helps companies in automotive industry meet EPA standards

Durability

Plastic parts are long-lasting and they don’t oxidize or corrode easily, while metal parts do corrode over time and require maintenance.

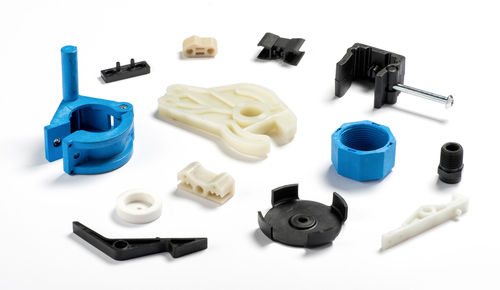

Design

Achieving complex textures and shapes is easy with the tooling used in plastic injection molding. However, designing complex shapes with metals requires complex and expensive tooling and processing.

Production and lead time

Manufacturing of plastic parts requires a less labor-intensive process than metal, resulting in quicker production and delivery.

Strength-to-stiffness and strength-to-weight ratio

Modern polymer composites perform equally well and better than metals in terms of strength. They typically have a higher strength-to-stiffness ratio – the resistance to deformation under stress per mass density, as well as a higher strength-to-weight ratio – the amount of stress a material can endure before failure divided by density.

Safety

During the process of handling, installing, or manufacturing metal, there’s a high risk of injury due to its heavy weight and sharp edges. Plastic features smooth edges and light weight, decreasing the possibility of injury.

What is a reputable plastic injection mold manufacturing company?

When you need high-quality injection molded parts, learning more about the common materials and proper ways of choosing an adequate surface finish and assembly method are crucial steps for successfully carrying out your project. At Wunder Mold, we’ll work with you throughout the entire process to ensure you receive the parts that match your needs and specific requirements.

We’re here to provide you with all the necessary information and advice such as whether your project requires any secondary machining process, as well as suggest the type of material that renders the features your product specifications require.

As a company that has been in the industry for more than 24 years, we incessantly strive to further advance the quality, cost-efficiency, and scope of our injection molding. With high attention to detail and the quality of our materials, processes, and workmanship, the benefits our clients reap are numerous. Give us a call or send us an email at sales@wundermold.com and let us know what we can do for you.