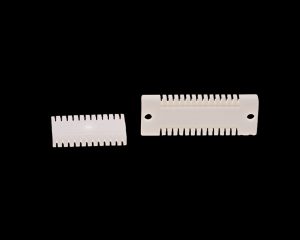

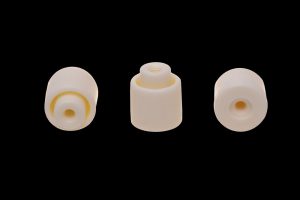

As a leading advanced technical ceramics manufacturer, Wunder-Mold is uniquely positioned to deliver high-precision molded alumina ceramic parts to clients in many industries. Our proven techniques and reliable methodology enable us to meet specific requirements and allow us to mold ceramic components in accordance with our clients’ detailed specifications.

At Wunder Mold, we use only high-quality powders and organic constituents in our injection molding feedstocks. This ensures that the components made for our customers are of high quality and consistently reproducible in order to provide the finest parts at the very best price.

Turn to us for your advanced ceramic needs & get the #1 manufacturer on your side

Discover the Wunder-Mold difference

Ceramic parts molded from high-quality materials

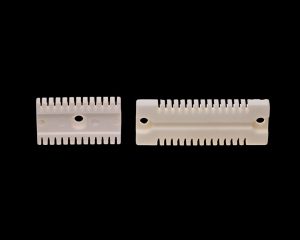

Tool design and manufacturing

Wunder-Mold’s product managers and engineers work closely with the customer to design a component that is easily molded and provides the best value. Then, using proven manufacturing methods, expertise and experience, the design is transformed into a high-quality injection molding tool that will produce the required part.

Injection molding

Wunder-Mold’s engineers design the cycle for aluminum oxide injection molding according to precise parameters to produce the best possible part. We utilize advanced equipment and tried-and-tested methods to ensure close tolerances for each part we manufacture, creating an efficient and cost-effective process with predictable results.

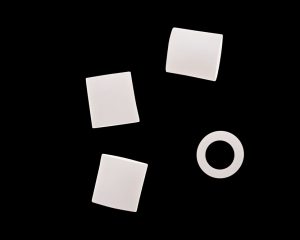

Debinding / sintering

The feedstock binder material of the molded part is removed in a carefully controlled procedure. The part with no binder is consolidated into a fully dense part using high temperatures in sintering furnaces. We keep the entire process, from start to finish, under complete control to make sure our custom ceramic parts created with alumina injection molding live up to the highest of standards.

Post-sintering process

If the ceramic components have requirements that cannot be obtained by Wunder-Mold’s closely controlled injection mold process, post-sintering surface grinding, honing, drilling or other secondary operations may be required to achieve the final dimensions. This will ensure that the component produced is of the required quality and to client specifications.

ISO 9001 quality

Following ISO 9001 guidelines, Wunder-Mold delivers strong quality control procedures that meet or exceed customer expectations.

Quality

Technology

Frequently Asked Questions

Can ceramic be molded?

Yes. Using a blended powder product called “feedstock” which is made from Alumina and a binder material, the feedstock is forced into a mold of the finished part under high pressure and literally molded into the desired shape. There are additional manufacturing processes after the molding, but the process starts with the injection molding process.

What ceramic capabilities do you offer?

Our ceramic molding capabilities include injection molding and other manufacturing processes which allow us to provide finished parts to our customers exact specifications. General capabilities include the following:

- Parts weighing from 0.1 g to 150 g

- Mold cavitation from 1 to 10 parts

- Tolerances down to +/- 1/2 % of dimension or 0.0005″

- Hole sizes down to 0.006″ (over a 0.100″depth)

- Wall thicknesses as small as 0.018″

- ID/OD grinding of ceramic parts

- Surface finishing of ceramic parts

- Assembly capabilities

How are ceramic parts made?

The manufacturing process of custom aluminum oxide ceramic parts is complex, involving multiple steps based on careful monitoring and precise production. This process entails the following aspects:

- Material selection: This part of the process involves the use of alumina powder that is mixed with an organic binder to form a feedstock, available in different purities of Alumina content. The choice of material depends on a client’s requirements, as different feedstocks are more suitable than others depending on the application.

- Injection molding: This mixture is then forced into a custom-made mold using high pressure so that the material takes the shape of the mold cavity. Once the part has been removed from the mold, it continues to the next step of the manufacturing process.

- Debinding/sintering: The custom ceramic molded component is then de-bound. This is a carefully controlled procedure which removes most of the binding material. It is then sintered at high temperature in a special sintering furnace. This procedure removes the last amount of binder, leaving only a dense ceramic part.

- Post-sintering: Depending upon the part specifications, it may be complete after sintering. But, if the part requires more operations in order to meet dimension and finish specifications, it then progresses to the next machining step which may include different types of grinding or bore finishing. These processes are capable of providing exact finished dimensions in the range of +/- two-tenths of one-thousandth of an inch.

- Inspection: Throughout the manufacturing process, parts are inspected many times to assure overall quality, always following procedures certified by ISO9001 protocol.

What are advanced ceramics?

Advanced ceramics are a special type of material that offers a unique set of features. They represent carefully produced compositions made of raw materials and binding solutions. Some of the main features of advanced, also known as engineered, technical or fine, ceramics include the following:

- Exceptional level of strength and rigidity

- Resistance to heat, pressure, and corrosion

- Versatile commercial application possibilities

- Outstanding electrical and insulation properties

- Biocompatibility necessary for medical application

Different types of advanced ceramics

Advanced ceramics represent a group of materials with exceptional features. They are manufactured through the alteration of raw materials and the use of advanced firing methodology. Each advanced compound brings a unique array of characteristics suitable for a particular industry. Some of the most widely used advanced ceramics include:

- Alumina

- Zirconia

- Silicon nitride

- Silicon carbide

- Aluminum nitride

Wunder-Mold is an advanced technical ceramics company that serves both the national and global markets. Our custom-made ceramic products are made of the finest materials. We provide high-quality zirconia and alumina ceramic molded parts.

Is aluminum oxide a ceramic?

Yes, aluminum oxide is a type of advanced ceramic material. It’s one of the most commonly used types of technical ceramics in injection molding. Our company takes into account your specific requirements regarding a component. Through an in-depth analysis, we determine which type of alumina is the most suitable choice for your needs.

What is alumina ceramic?

Alumina is a widely used type of fine ceramics known for its strength and reliability. It features both electrical and mechanical properties that make it suitable for application in a number of different industries. Alumina ceramic parts are typically characterized by:

- Biocompatible features

- High electrical insulation

- High thermal conductivity

- High resistance to corrosion

- Great strength and hardness

- Resistance to wear and pressure

- Stability in high-temperature situations

What is alumina used for?

Parts made from the alumina injection molding process have diverse commercial applications. The finished components are used in a range of different industries, including:

- Medical and dental applications

- Automotive components

- Electrical parts

- Engineering

- Filtration

Of course, these are just some of the possible fields where these components can be used. As a technical ceramics company, Wunder-Mold can advise you on the best product for your needs and handle its manufacturing. We can customize alumina ceramic parts to your preferences, creating a specific shape or size required by industry guidelines.

What is alumina made of?

Alumina is made of natural ore called bauxite through the Bayer extraction process. This chemical compound contains both aluminum and oxygen molecules. After being extracted from bauxite, it resembles a white powder. Sapphire and ruby are its free forms in nature.

Furthermore, injection molded ceramics made of alumina can feature different purity levels and can be used in combination with other materials. For instance, we use alumina toughened zirconia, which results in a compound of exceptional toughness, hardness, and wear resistance.

Whether you’re interested in learning more about alumina-based custom molding or want to know more about our other ceramic materials, don’t hesitate to contact us. Our customer support team is ready to answer your questions and provide you with a personalized client experience.

Where to find the best of technical ceramics companies?

Injection molding is a cost-effective way of delivering high-precision components made of the strongest ceramic materials on the market.

We employ proven techniques and advanced equipment, using the strongest and most pure ceramic materials – alumina and zirconia. Our custom molding services are available to businesses that need new, custom made parts for optimal results.

However, we also offer custom-designed plastic injection molding services that will enable you to reduce your manufacturing costs and improve the performance of your existing components.