The manufacturing of aluminium oxide is a complicated process that requires experience, knowledge, and adequate equipment. It is similar to the process of manufacturing zirconia in terms of the complexity and expertise necessary to fully take advantage of all the characteristics this advanced ceramic material has.

Also, the alumina injection molding company you choose to partner with has to have the capability and the know-how to produce alumina fit for varying purposes of different clients. While the innate hardness of zirconium oxide has its specific uses, alumina remains one of the most widely-used advanced ceramic materials, so let’s see how it’s made and if you can machine it.

How is alumina ceramic made?

Alumina is, arguably, the most widely-used advanced ceramic material, and it is made from the naturally-occurring ore called bauxite by implementing the process of Bayer extraction. The chemical compound of bauxite contains both oxygen and aluminium molecules.

Alumina is, arguably, the most widely-used advanced ceramic material, and it is made from the naturally-occurring ore called bauxite by implementing the process of Bayer extraction. The chemical compound of bauxite contains both oxygen and aluminium molecules.

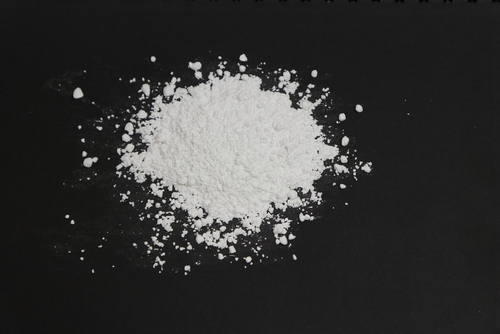

Once aluminium oxide is extracted from bauxite, it looks similar to a regular white powder. For example, other forms of alumina that occur freely in nature are precious gems of ruby and sapphire.

Alumina advanced ceramic can be produced implementing several different manufacturing processes. These processes include extrusion, isostatic pressing, and injection molding. The finishing of alumina ceramics can be done using laser machining, precision grinding, or other processes.

However, alumina injection molding remains the most suitable alumina manufacturing process due to various possibilities for component design. This allows alumina ceramic manufacturers to cater to the varying needs of clients from different industries.

How do you make alumina through injection molding?

The alumina injection molding process consists of four vital steps that ensure maximum end-product quality, durability, and suitability for client’s purposes:

- Tool designing and manufacturing: First, experts design and manufacture molding tools necessary for producing the part required by the customer.

- Injection molding: Engineers design custom injection molding cycles necessary for producing the adequate component.

- Sintering/de-binding: This part of the process involves the removal of the feedstock binder material present in the molded part. Then, the part without binder undergoes the sintering process to become fully dense.

- Post-sintering: Finally, different post-sintering procedures, such as drilling, honing, or grinding, ensure the product perfectly matches client’s specifications and requirements.

Can you machine alumina ceramic?

That is why professional alumina ceramic manufacturing companies usually machine alumina after sintering using high-quality diamond-coated tools. These tools help abrate the material away until the desired form of alumina ceramics is created.

This type of machining process will guarantee that alumina ceramic will retain precise dimensions after machining. However, alumina is hard and tough, and this process tends to be expensive and time-consuming.

That is why it is important to partner with a company that injection molds alumina to near net size in large quantities. This will help reduce overhead costs, helping you receive a lower price for alumina advanced ceramic components and products of an equally high quality.

Which reputable alumina injection molding company do I partner with?

Wunder Mold is an alumina injection molding company that utilizes cutting-edge equipment and advanced molding processes to ensure the highest quality of all our alumina ceramic products. We employ qualified and knowledgeable alumina injection molding experts who listen to your specific requirements and design solutions that will solve the needs of your business.

With over twenty-five years in the alumina injection molding industry, we possess the experience necessary to manufacture durable, hard-wearing and long-lasting alumina ceramic that will perfectly suit your needs. Contact us at (707) 448-2349 or send us an email at sales@wundermold.com. We’re here to help you improve your operations any way we can. Reach out today!