Knowing how zirconia ceramic is made is the first step in becoming aware of all the potential uses this incredibly versatile material can have in different industries. Zirconia possesses many properties that make it suitable for production of different parts and products meant for varied professional purposes.

Similarly to the manufacturing process of aluminium oxide ceramic that allow alumina to be used for a variety of purposes, it is important to be familiar with how experts perform zirconia injection molding and see if components made from zirconia will be beneficial for your business. Let’s see more about it.

Is zirconia a ceramic?

Is zirconia a ceramic?

Zirconia, or zirconium dioxide (ZrO2) is a crystalline oxide of zirconium. It is white or black in color, and it naturally occurs most commonly in a monoclinic crystalline structure. Zirconia is one of the most frequently studied materials.

Zirconia is a ceramic material and it possesses many advanced mechanical properties that make it suitable for use primarily in various medical devices, but also in different industries that have need for parts and products manufactured from zirconia.

The question of whether or not zirconia is a ceramic occurs because it contains atoms of metals in its structure, similarly to other types of ceramic materials. This allows zirconia to combine the high innate strength of metal with the biocompatible aspects of ceramics.

To conclude – zirconia is a ceramic with some metal-like properties that makes it suitable for specific implementations.

How is zirconia ceramic made?

Zirconia is commonly created through the process of calcining different compounds of zirconium. Calcination is a method that includes the heating of a certain material to high temperatures without or with a limited presence of oxygen or air.

The main purpose behind this process is to remove any impurities, but also to bring about a thermal decomposition, which creates a molten compound of zirconium oxide, or ZrO2 suitable for subsequent manufacturing processes.

- Designing and manufacturing of necessary tools: The first step is to always design a product that can be easily created through injection molding and to plan a process that ensures maximum value of the end-product.

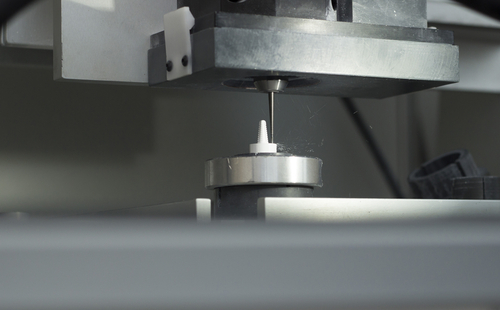

- The process of injection molding of the part: Once the necessary injection molding tool for the desired product has been made, professionals design the injection molding cycle and create a high-quality product.

- Additional processing of the molded part: When the injection molding process is complete, it’s time to remove the feedstock binder material from the molded part and implement high temperatures of sintering furnaces to consolidate the part without binder into a single dense product.

- Different post-sintering processes if needed: If the exact dimensions and specifications cannot be attained only through injection molding, it is necessary to perform additional post-sintering operations, such as surface grinding, drilling, and honing.

Who are the leading zirconia injection molding experts?

Wunder Mold is a company that specializes in zirconia injection molding for various specialized applications. We manufacture different components and parts from zirconia per our customers requirements and specifications using technologically advanced zirconia injection molding procedures and process machinery. This helps us achieve superior-quality products our customers will be satisfied with. Our designing and manufacturing staff is here to ensure you receive the best product to suit your specific needs.

With more than 29 years of experience in the alumina and zirconia injection molding industry, we have the necessary experience, knowledge, and qualifications to translate your ideas into products your company needs. Provide detailed specifications of your desired products and our dedicated staff will work with you to bring them into reality. Reach out to us by sending an email at sales@wundermold.com or by calling us at (707) 448-2349.