Ceramic injection molding is one of the most versatile, efficient, and popular manufacturing processes for a wide range of intricate components. However, if you partner with the wrong ceramic injection molding company, you can easily find yourself paying high prices for your products and struggling to retain a favorable bottom line. That’s why you need to acquire information on how to cost-effectively outsource your CIM requirements.

How do I cost-effectively outsource my ceramic injection molding?

Outsourcing your company’s needs for ceramic injection molded parts is a crucial business decision that strongly affects your finances. In order to find a manufacturer that fits your financial bill, you have to first know the staples of a cost-effective process. From there, it’s all about choosing a company that implements the following manufacturing practices:

Choosing the right materials

Choosing the right materials

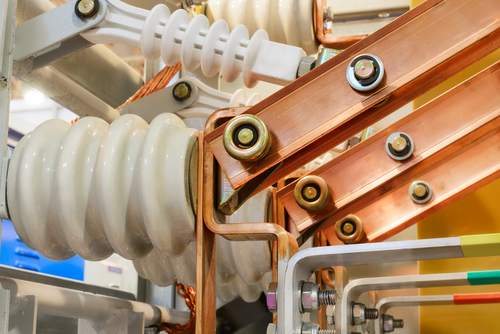

The first consideration for any company that deals with ceramic molding is the choice of materials for each separate component. There are numerous variations of ceramic materials used for injection molding, including alumina, zirconia, and various other combinations.

First, the physical, thermal, conductive, and other vital properties depend on the choice of materials. However, so does the cost of production. Your manufacturer of choice should use the most cost-effective material available that provides the properties you require.

Identifying opportunities for process consolidation

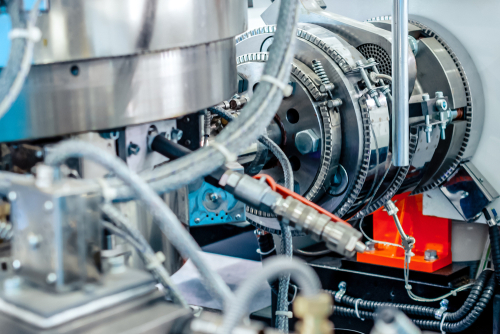

You need to find a company that consolidates the various critical aspects of ceramic injection molding into a single, robust process that will serve as a financially viable solution. For example, your manufacturer should unify different ancillary processes, such as painting, label printing, custom inserts, and others into one fluid and consolidated endeavor.

Selecting the right company size

When you’re trying to find the best provider of CIM services, it’s essential to choose a company whose size and operational capacity fit your requirements. There are small, medium-sized, and large manufacturers with varying machinery and tools, and hiring one that fits your needs is very important.

For example, if you require large volumes of overly-intricate components, going for a small company with equipment that has difficulties producing the part you need in high volumes will only drive the price up due to the inefficiency of the process and unsuitability of the machinery they own.

On the other hand, if you require a small or one-time volume of simple components, going for a large corporation is a waste of resources for both you and the manufacturer. Utilizing cutting-edge machines capable of producing high volumes of complex parts for low volumes of simple designs will drive the costs up.

Considering bulk production

The more identical parts you produce through ceramic injection molding, the lower the price of each individual component will be. That’s why you should always plan ahead, inspect your available resources, and go for bulk production if possible. The larger initial investment is well worth the overall reduction in price that comes from manufacturing higher volumes of a single product.

Which reputable ceramic injection molding company should I outsource to?

However, if you just want a ceramic injection molder who already has the most cost-effective production processes, reach out to Wunder Mold. We manufacture different types of ceramic components for a wide range of specialized applications across many industries. We combine high-quality materials and advanced tools to give you a part your company requires. Give us a call today or send us an email at sales@wundermold.com.