Automating the process of plastic injection molding offers numerous advantages to both the manufacturing company and the end user. However, not all plastic injection molding processes can be automated, and knowing which ones you should automate and how to adequately do so requires experience, knowledge, and qualifications only the leading molders have. Let’s take a look at how professionals automate certain processes and ensure production of high-quality plastic injection moldings.

What is automated plastic injection molding?

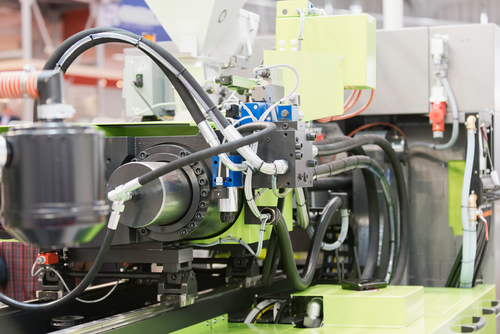

Automated plastic injection molding makes good use of combining various robotic manufacturing equipment and automation tools into a coherent automated production process. This allows for faster, easier, and more reliable handling and manufacturing of even the most delicate plastic parts.

What are the benefits of automated molding?

Better machine utilization

Automated plastic injection molding systems are interconnected. They communicate with each other through a centralized control system. This interconnectivity and cross-communication allows data collection and analysis that identifies areas of improvement and further boosts the manufacturing process. Additionally, the data helps operators and engineers notice part and equipment failures.

Quicker production

Robotic molding systems can efficiently move through different stages of the proces without interruption. Such systems, if installed, maintained, and serviced correctly, can operate 24 hours a day, which results in faster order completion and better production per unit.

Lower labor costs

Some segments of the production process require the involvement of several people. With the introduction of robotics into plastic injection molding, these processes became fully automated, significantly lowering labor costs associated with them. This allows companies to take on larger orders without the need to increase the number of staff members.

Improved fabrication sustainability

Machines created larger volumes of desired products with lower error rates. This not only improves fabrication efficiency and sustainability, but it also reduces waste generated by deformed and rejected parts.

Increased workplace safety

Finally, use of robotics in the more dangerous parts of the injection molding process ensures staff members are out of harm’s way, which significantly reduces the potential for injury during manufacturing.

What injection molding processes can be automated?

Not every portion of the injection molding process can be automated – some parts still require an experienced professional to perform and oversee it. Most notably, experts are still essential for designing and ensuring the product meets the necessary specifications. However, different parts of the process can be automated to boost efficiency:

- Loading & unloading: Robots are capable of efficiently operating in constrained areas and load and unload machinery faster than employees while eliminating human errors and improving safety.

- Quality control & vision inspection: Robotics allow engineers to oversee the process of inspection and quality assurance by allowing for faster part orientation and by using sensors to detect dimensional errors.

- Sorting, stacking, and assembly: Robots can also complete complex tasks after the molding process. These tasks range from welding to sorting and arranging finished components for packaging.

- Different secondary processes: Finally, robots will handle various post-production procedures, such as labeling and decorating.

Which company produces high-quality plastic injection moldings?

The complexity of custom plastic injection molding demands experience and expertise to perform correctly. That is why you should only partner with Wunder-Mold, the leaders in plastic injection molding. We have more than 29 years of experience manufacturing various components and parts that conform to our customer’s exact requirements. You can reach out to us at sales@wundermold.com or call (707) 448-2349. We’ll give you the part you need!