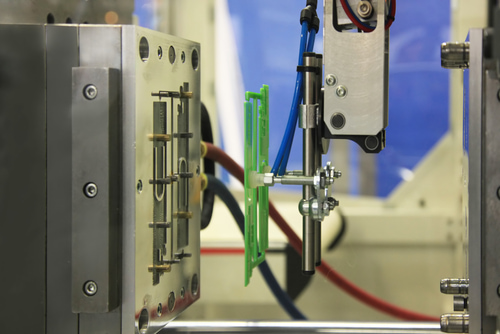

Plastic injection molding is the most popular, efficient, and cost-effective method for manufacturing various plastic parts and components for a variety of applications. Plastic injection molding manufacturers take your requirements into consideration and translate them into a finished product ready for mass production. It is this type of customization and precision that makes plastic molding suitable for a variety of components.

What are the most common parts created with plastic injection molding?

Plastic injection molding is an extremely versatile process capable of producing numerous specialized components for a variety of industries. Here are some of the most common products made by plastic injection molding.

Common parts and components made with plastic injection molding

Some of the most frequent uses of the plastic injection molding is for manufacturing products in the following categories:

- Healthcare industry products: The healthcare industry arguably uses most plastic molded products. There are literally thousands of plastic parts and components that see daily use in this field, from disposable bins and medical trays to disposable syringes.

- Automotive components: Automotive industry takes advantage of resin customization and additive incorporation to create strong and durable parts such as bumpers, dashboards, cup holders, and other invaluable automotive components.

- Household items: Some of the most common household items produced by plastic injection molding are various drinkware, containers, closures, as well as disposable cutlery, cups, etc.

- Agricultural products: Plastic offers high impact resistance, exceptional humidity resilience, and great temperature resistance, making it suitable for a wide range of parts and components used in different agricultural fields.

- Toys: Plastic is durable, doesn’t corrode, lightweight, and safe for kids to use, making it perfect for creating all kinds of toys. One of the most popular brands in the world, Lego, uses plastic injection molding for manufacturing of its popular building blocks. But that’s just one of the numerous examples of plastic injection molding being used to make toys.

- Electronic housings: Plastic injection molding is suitable for mass production of various electronic housing components used in a variety of devices, such as televisions, computers, and remote controls. Plastic injection molding allows companies to manufacture large quantities of custom enclosures of virtually any size, shape, and application.

- Plastic bottles: Finally, plastic bottles are, without a doubt, the most commonly-produced item that utilizes the technology of plastic injection molding. Polyethylene terephthalate is mostly used for plastic bottles for its lightness and strength.

Other parts and components made with plastic injection molding

Plastic injection molding is also suitable for production of other specialized products commonly found in these industries:

- Sporting goods:

- Exercising tools

- Training devices

- Food service:

- High-temperature trays

- Bread trays

- Home products:

- Flower pots

- Air fresheners

- Wire ties

- Hobbies:

- Collectible models

- Consumer goods:

- Toilet seats

- Tackle boxes

- Bird feeders

- Residential construction:

- Deck fasteners

- Railing gaskets

- Roofing vents

- Commercial products:

- Insulators

- Concrete beam conduits

- Raised flooring panels

Who are the best among plastic injection molding manufacturers?

Or you can simply contact Wunder Mold – the leading plastic injection molding company that manufactures advanced parts and components per your specific requirements. We carefully choose the most suitable resin for your part, design the production process, and proceed to manufacture it in the exact quantity and quality you require. Reach out to us at sales@wundermold.com or call (707) 448-2349.