In recent years, ceramics in injection molding have seen a remarkable popularity. The ability to produce high-performance components in complex shapes is making this manufacturing option more and more desirable, as it continuously pushes the boundaries of design, functionality, and material durability.

Certain industries are increasingly opting for CIM to meet the demands of production, making it a top choice for creating shapes that were previously challenging, if not outright impossible to create. So, what are the industries that see a continuous demand for Ceramic Injection Molding? Read on and let’s find out.

What industries use injection molding?

The nature of CIM makes it a very attractive option for multiple industries. Ceramics have proven superior to plastics in demanding scenarios, and on top of that, allow the creation of intricate and complex shapes that are hard to achieve with traditional ceramic manufacturing. These two combined benefits have made CIM very effective in streamlining production processes, increasing the demand for ceramic parts in various sectors. Let’s take a look at some of them:

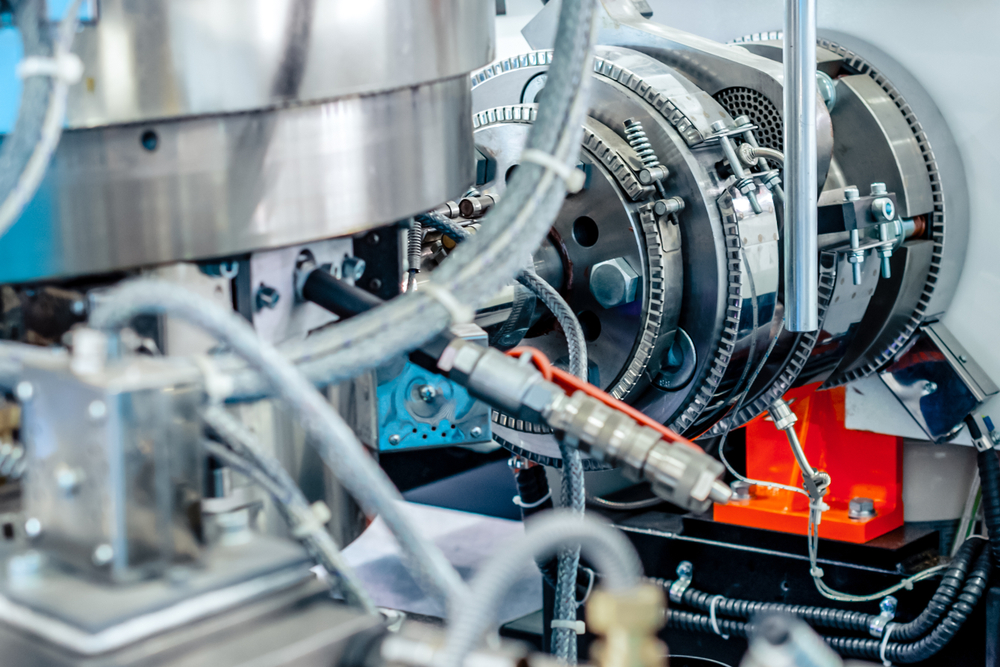

1. Industrial machinery

High durability, wear resistance, and thermal stability in high-performance operations make ceramic components invaluable in industrial applications. Cutting tools, valves, bearings, and other components are seeing increased use in scenarios where metal or plastic components are proving less effective, overall resulting in an ever-increasing demand for ceramic manufacturing. As CIM allows intricate and complex shapes that traditional ceramic production struggles with, machinery that requires precision is increasingly relying on ceramic parts.

2. Electronics

CIM is increasingly meeting the demand for reliable semiconductors, batteries, and other components used in various electrical parts. Thanks to the inherent nature of ceramics providing electrical insulation and being resistant to heat, molded parts are an excellent choice in various high-performance electronics.

3. Telecommunications

In the telecommunications industry, CIM plays a crucial part in manufacturing highly precise and intricate parts used in various networking equipment. The ability to create complex shapes that would be otherwise difficult, if not outright impossible, to replicate with conventional methods is especially important as more and more communication devices have become more compact and high-performing at the same time.

4. Automotive & aerospace

In the automotive and aerospace sectors, CIM supports the production of various components that have to endure heat, friction, and mechanical stress. This is especially true for the aerospace industry, where certain components have to endure extreme temperatures and pressures.

Near-net-shape production can greatly streamline the assembly process, while at the same time ensuring each part meets strict industry standards. And best of all, ceramics are resistant to corrosion.

5. Medical field

CIM, in particular, can meet the demand for precision in the medical and healthcare industries. Some of the most common uses include dental prosthetics, implants, and medical sensors. The biggest advantage of ceramics in this case use scenario is the fact that it’s biocompatible, which allows them to fuse with the human body without causing a reaction. On top of that, unlike metal, ceramics are resistant to bacterial infections.

Which company specializes in reliable injection molding?

With over 3 decades of experience in injection molding, Wonder Mold brings advanced equipment, lasting solutions, and proven expertise to meet the unique demands of modern manufacturing.

Thanks to the comprehensive knowledge of injection molding, our experts will go above and beyond to ensure that molded parts adhere to the highest industry standards. Whether you need our services in the U.S. or across the globe, feel free to contact us at sales@wundermold.com or via a phone call, and we’ll set up an appointment to discuss the needs of your project. Reach out today!