Advanced ceramics are an extremely strong material. The raw materials used to manufacture advanced ceramics make them very durable and suitable for use across many different industries. Technical ceramics are also incredibly heat resistant, which further increases their versatility.

However, some people mistake technical ceramics with traditional ceramics, and it is sometimes this misconception that makes them inquire about the strength and durability of advanced ceramics. Aluminium oxide ceramic companies produce specialized advanced ceramics compounds that are strong and reliable. Let’s see how strong.

Are advanced ceramics strong?

Are advanced ceramics strong?

Advanced ceramics are a very strong material. Numerous specialized applications of advanced ceramics demand they have specific properties to make them suitable for different uses. Strength is one of the most sought-after characteristics of advanced ceramics, as it is a requirement for a vast majority of uses.

Advanced ceramics possess three different types of “strength” that allow them to be the perfect choice of material in different industries. Let us take a closer look at how strong technical ceramics are under different conditions and in different circumstances:

- Tensile strength: Tensile strength measures the force required to strain a material to the point of breaking it. Tensile strength is measured in the maximum amount of tensile stress needed to break a material. Advanced ceramics possess excellent tensile strength under regular conditions.

- Compressive strength: Compressive strength is the ability of a material to resist compression, which is a vital characteristic for structural design. Technical ceramics possess exceptionally high compressive strength, higher than their tensile strength. This makes them ideal for uses where ceramics parts remain in compression.

- High-temperature strength: High-performance applications require materials to retain strength under high temperatures. Advanced ceramics are able to retain most of the room-temperature strength at very high temperatures. Also, they revert to original properties when returned to normal temperatures.

It is these specific “strengths” that make advanced ceramic suitable for use in demanding environments. Not only are advanced ceramics strong under regular conditions, but they are able to retain their desired properties both in compression and at high temperatures.

What is the strongest ceramic material?

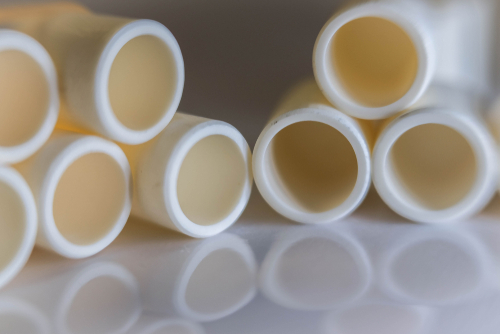

- Alumina: Alumina is, arguably, the most widespread advanced ceramics compound. It is a chemical compound of oxygen and aluminium, and it offers excellent abrasion resistance, thermal conductivity, chemical and high-temperature resistance, as well as electrician insulation.

- Zirconia: Zirconia is white or black in color. It is almost as widely used as alumina, and it is completely chemically unreactive. It provides abrasion, mechanical, and high-temperature resistance. It is most commonly used for appearance parts because of its aesthetic properties.

What is the leading aluminium oxide ceramic company in the country?

Wunder Mold not only knows all about the strength and other numerous benefits of advanced ceramics, but we also know how to make the toughest advanced ceramics available on the market. We employ the most modern advanced ceramics manufacturing techniques and equipment to produce the finest ceramics.

With over 29 years of experience producing advanced ceramics, we are able to translate all your needs and wishes into reality. We will provide you with the solutions per your requirements. Contact us at sales@wundermold.com, or dial (707) 448-2349 and tell us what you want us to do. Reach out to us today!